登入

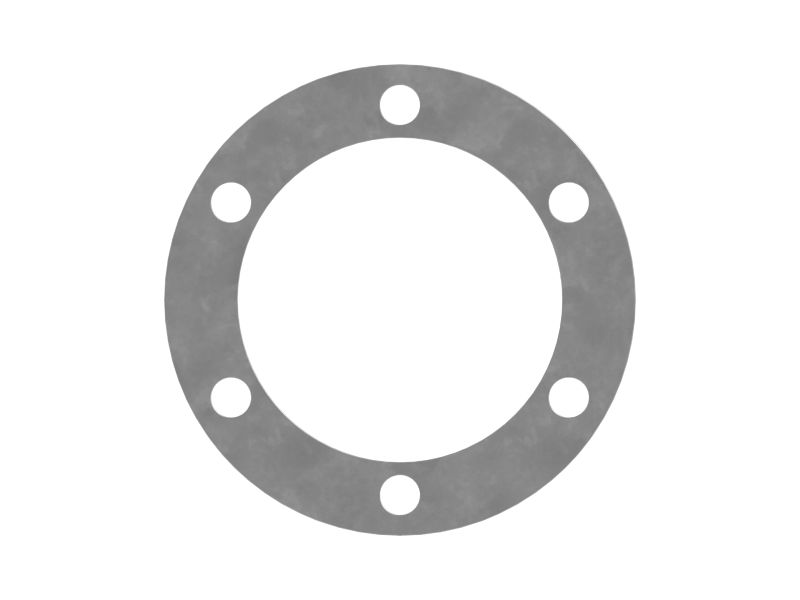

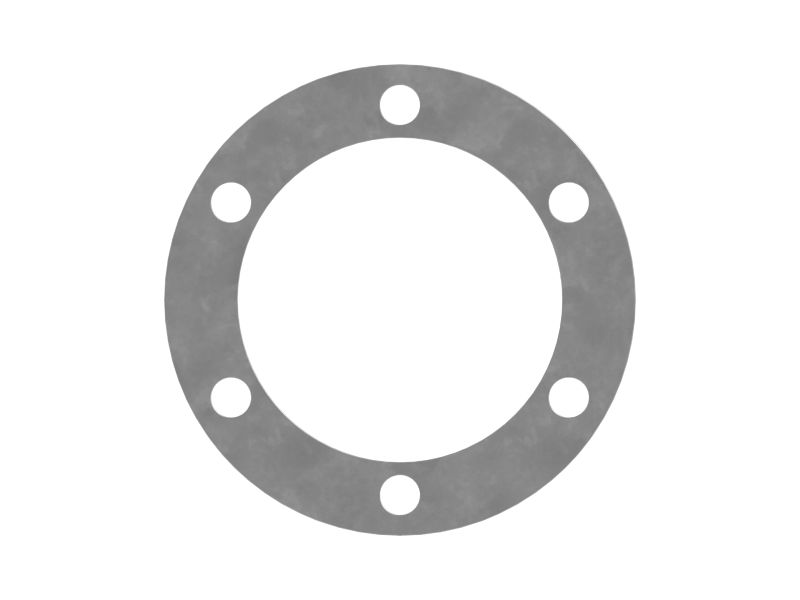

Cat® 2.97mm 厚墊片,用於鉸接裝置

品牌: Cat

Cat® 2.97mm 厚墊片,用於鉸接裝置

品牌: Cat

此零件根據製造商的規格設計以適合您的 Cat 設備。

對製造商配置的任何變更都可能導致產品不適合您的 Cat 設備。購買前請洽詢您的 Cat 代理商,以確保此零件適合您的 Cat 設備的目前狀況和假設的配置。此指標不能保證所有零件的相容性。

再製造

不可退貨

套件

已更換

再製造

不可退貨

套件

已更換

登入

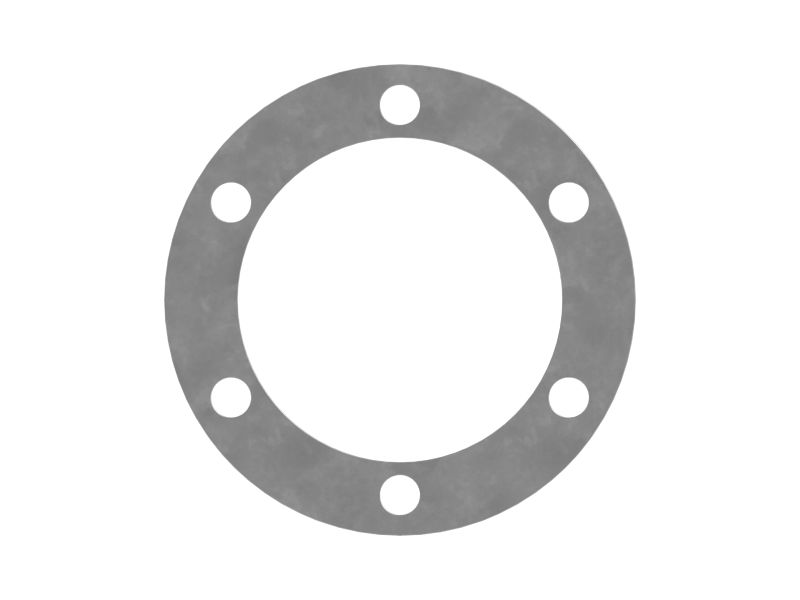

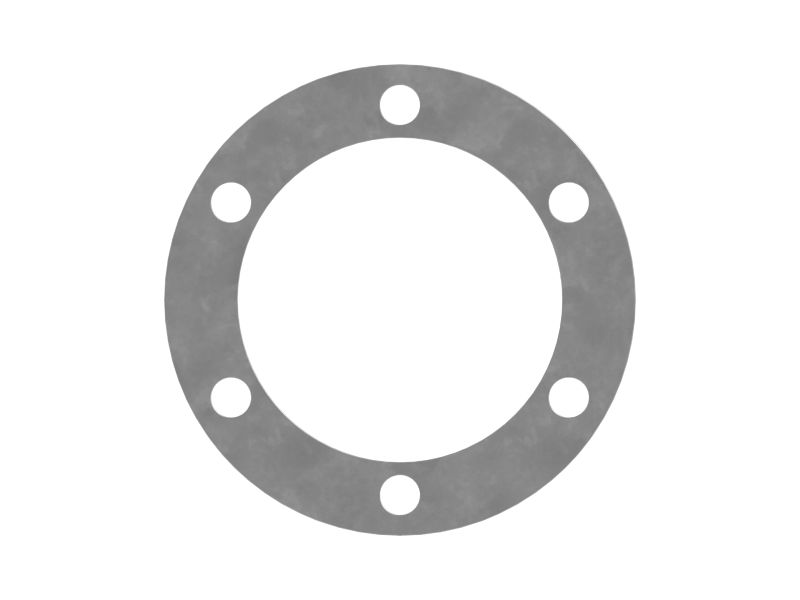

Cat® 2.97mm 厚墊片,用於鉸接裝置

品牌: Cat

Cat® 2.97mm 厚墊片,用於鉸接裝置

品牌: Cat

此零件根據製造商的規格設計以適合您的 Cat 設備。

對製造商配置的任何變更都可能導致產品不適合您的 Cat 設備。購買前請洽詢您的 Cat 代理商,以確保此零件適合您的 Cat 設備的目前狀況和假設的配置。此指標不能保證所有零件的相容性。

再製造

不可退貨

套件

已更換

再製造

不可退貨

套件

已更換

選取商店

了解價格和供應狀況

選取設備